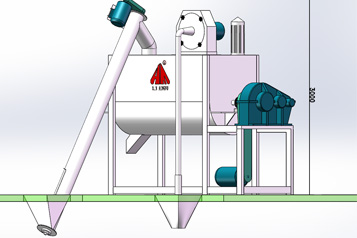

Hammer feed mill

Posted by Animall Feed Blok Making Machine | updatetime 2021-04-02 10:18

Hammer feed mill is consists of hopper, closed magnetic separator, guiding mechanism, upper case, operation door, rotor, machine base and shock absorber.

The raw material is fed by the feeder on the top of the machine, through hopper and magnetic separator, then fall into the crushing cavity through the guiding mechanism, it is gradually crushed under the impact of the high-speed rotating hammer and the friction of the sieve plate, under the action of centrifugal force and airflow, the smaller particles that have been crushed pass through the screen holes and are discharged out of the crushing chamber, and are transported away by the suction and discharge device through the discharge port of the base.

Its main parts are also vulnerable parts, including hammer and sieve. The shape of the hammer has a rectangular double-hole hammer with two symmetrical pin holes, which can be used for 4 times by changing the angle and turning around. At the same time, its vulnerable parts also including pin roll and elastic ring.

| Error phenomenons | Error reasons | Exclusion methods |

|

Difficult to start the motor

|

1. The power supply voltage is too low. 2. The cross-sectional area of the wire is too small. 3. The starting compensator is too small. 4. Fuse blown. |

1. Start after peak electricity consumption. 2. Change the appropriate wire. 3. Change to a suitable compensator. 4. Change the fuse suitable for the motor capacity. |

|

Motor overheated and weak |

1. Motor two-phase operation. 2. Short circuit of motor winding. 3. Long-term overloaded work. |

1. Connect to open phase, three-phase operation. 2. Overhaul the motor. 3. Rated load operation, change to a motor if necessary. |

|

The machine vibrates strongly |

1. The hammers are installed incorrectly. 2. The quality of the corresponding group of hammers is too poor. 3. Individual hammers have not been throw off. 4. Other parts on the rotor are unbalanced. 5. Spindle bending. 6. Bearing damage. |

1. Reinstall the hammer. 2. Re-exchange, the difference should not be greater than 5 grams. 3. Make the hammer rotate flexibly. 4. Re-balance and check rotor. 5. Straighten or change to new shaft. 6. Replace with new bearings. |

|

abnormal noise in the crushing room |

1. Iron and stone hard objects enter the machine. 2. The parts inside the machine fall off or are damaged. 3. Hammer screen gap is too small. |

1. Stop the machine and clear hard objects. 2. Shutdown inspection, troubleshooting and repair. 3. Change the gap to meet the requirements. |

|

Production is significantly reduced |

1. Insufficient motor power. 2. The hammer is severely worn. 3. Uneven feed of raw materials. 4. Raw material moisture content is too high. 5. The mesh size does not match. |

1. Repair or replace the motor. 2. U-turn or replace with a new hammer. 3. Feed evenly. 4. Dry the raw material. 5. Replace the suitable sieve plate. |

| Reverse spraying at feed inlet |

1. Conveying pipeline is blocked. 2. Screen hole blocked. |

1. Unblock blockages. 2. Clean up the sieve hole or replace the sieve. |

|

The finished product is too rough |

1. Perforated or severely worn screen. 2. Screen side clearance is too large. |

1. Replace the new sieve plate. 2. Shut down to make the screen plate and the screen frame fit tightly. |

|

Bearing overheating |

1. Too much or not enough grease in the bearing. 2. Bearing damage. 3. Bent spindle or unbalanced rotor. 4. Long-term overload work. |

1. Replace the appropriate amount of grease that meets the specifications. 2. Replace with new bearings. 3. Straighten the main shaft and balance the rotor. 4. Reduce the amount of feed. |

| There is noise in the coupling |

Damaged elastic ring. |

Replace with new elastic ring. |

Currently, our company's SFSP water drop crusher uses advanced teardrop-shaped grinding chamber design, secondary crushing structure, effectively destory circulation, increase production, more uniform grinding degree. Hammer mill rotor balancing by check, equipment operation less vibration, less noise, more stable. There are many output models, suitable for large, medium and small feed factories. If you need it, please contact me!

Leave your comment Here